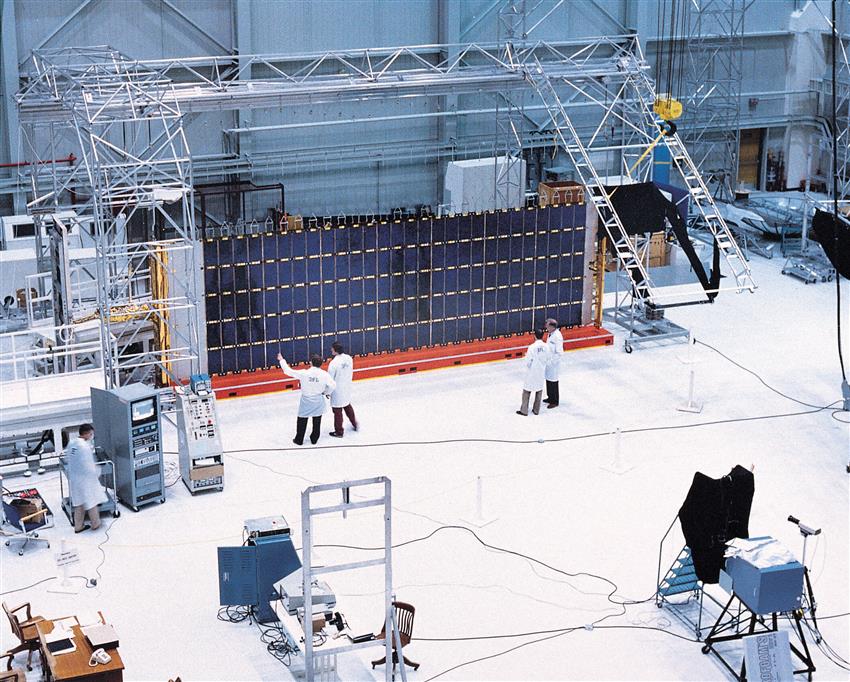

Integration and Assembly Areas

Please note that David-Florida Laboratory operations will be terminated by . Information related to this section may be consulted for reference purposes only.

The Integration and Assembly Areas of the David Florida Laboratory (DFL) are situated within three temperature- and humidity-controlled, high bay clean rooms of which High Bay 3 is the largest measuring 1,080 sq m (11,600 sq ft). When required, Class 1,000 or better clean room conditions can readily be made available. Each of the high bays are independently traversed by travelling bridge cranes. Access to the high bays is through security-controlled, air showers for personnel. A large loading bay with an overhead crane serves as the access point for all equipment entering the DFL. Two freight elevators provide access to the workshop and storage areas which are located in the basement.

Particulars

Net rentable high bay space

- High Bay 2: 180 sq m (1,940 sq ft)

- High Bay 3: 650 sq m (7,000 sq ft)

Small loading bay

- High Bay 1: 37 sq m (400 sq ft)

Large loading bay

- High Bay 3: 124 sq m (1,335 sq ft)

Storage areas

Available storage

- On-site and heated: 465 sq m (5,000 sq ft)

- Racks and bulk storage of items up to 4.8 m high (16 ft)

Additional storage can be arranged through a third-party supplier.

Associated customer support facilities

Accommodations

- Adjacent offices provide excellent work areas for our clients

Conference facilities and meeting rooms

- Three conference facilities range in size from 12 to 80 seats

- Meeting rooms for 10 to 20 people

- Other meeting areas are available throughout the Communications Research Centre (CRC) campus

Environmental controls

- Offices within the DFL are individually controlled for heating, ventilation and air conditioning (HVAC), and lighting. After regular working hours, occupancy override, ventilation, and carbon dioxide monitoring meets ASHRAE guidelines.

- Our Class 100,000 clean rooms can achieve particle counts as low as 10,000. Each of the qualification facilities and high bays have independent HVAC controls with three-stage filtration. The HVAC system is capable of maintaining a year-round temperature of 22 ±2 degrees C (72 ±4 degrees F) plus a relative humidity of 40 ±5% in the winter and 45 ±5% in the summer.

Safety and security

- The safety and protection of valuable spacecraft and hardware receive the highest priority at the DFL. The DFL provides this high level of security for all of its test activities because it is located within the CRC campus which has its own state-of-the-art security measures in place including controlled access to the campus itself, to the DFL, and to its various secure facilities. Perimeter access doors are controlled and monitored.

- The building is equipped with state-of-the-art fire protection/fire detection systems

- Office areas are equipped with sprinklers and fire protection and fire detection systems

- Qualification facilities and clean rooms have an addressable fire detection and/or controllable fire protection system

- Both security and fire detection systems are monitored 24 hours per day by CRC security

Building systems

- Central heating (5,000 MBH), central cooling (400 ton), and emergency power generators (1.5 MW and 350 kW) serve the entire DFL building

- Each building system has adequate capacity and redundancy to ensure safe and continuous operation year-round and with minimum maintenance down-time

Power supplies and generators

Emergency power supplies and generators

- Main diesel generator: 1.5 MW generator provides backup power to the DFL and storage building number 87

- Backup diesel generator: 350 kW

Note: This generator is a backup to the 1.5 MW generator and is dedicated to essential building services, the thermal qualification facilities, and the structural qualification facilities

Uninterruptible power supply

- Two 15 k VA uninterruptable power supplies are available to provide power backup to critical systems during power surges or transitions.

- One of them is dedicated for use by the Thermal Qualification Facilities and the other one is dedicated for use by the Structural Qualification Facilities.