The SWARM project

Canada continues to lead the way in developing practical, on-the-ground applications for space exploration.

Did you know that Canada has an impressive history of achievement in developing technology that allows us to make direct contact with the surface of the Moon? In the s, the Canadian company Héroux (now called Héroux-Devtek) manufactured the legs of the lunar landing gear used during the Apollo missions. More recently, the Canadian Space Agency (CSA) worked with the Canadensys Aerospace Corporation on the Scalable Wheels and Advanced Rover Motion (SWARM) project to develop a special wheel prototype that could withstand the rigours of lunar and other extraterrestrial surfaces and allow us to travel longer and farther. This project was funded by the CSA under the Space Technology Development Program (STDP).

One of our biggest responsibilities at the CSA is to ensure that the equipment and technology we use to explore space is efficient and dependable. Testing here on Earth must be rigorous and realistic, which can be challenging because lunar and other planetary conditions are quite different from those on Earth – they may change very rapidly and in some cases are completely unknown.

The SWARM project is all about "rolling forward" with ingenuity, inventiveness and persistence in the face of multiple challenges and shifting conditions. This project provided Canadian scientists and engineers with an opportunity to develop transportation technology that will also be helpful here on Earth to traverse off road and other challenging terrains. Once again, Canada is playing a pivotal role in developing practical, on-the-ground applications that allow us to explore lunar and other planetary surfaces.

"Mobile robots need to be mobile."

One of the key lessons learned during Canada's experience working with rover technology since the early s is that we need a flexible wheel that can travel dependably in different environments. On Earth, almost all vehicles use rubber tires to move on various terrains. Rubber provides excellent traction and can adapt its geometry (flexibility) as wheels move over obstacles. Unfortunately however, rubber wouldn't be reliable on other planets. In extreme cold it becomes brittle and breaks, and in a vacuum, rubber particles may out-gas and evaporate. Rubber tires are also usually inflated with air, and if they spring a leak in the absence of a pressurized atmosphere, they cannot be re-inflated.

"When you can't use a rubber tire, you have to rethink your entire rover design as well. These vehicles must be designed as a holistic system – in order to get the mobility you need, every component must work together with everything else."

So how do we reproduce the mechanical properties of a rubber wheel in space? In order to address this problem, the CSA asked Ontario company Canadensys Aerospace to design, develop and test scalable wheel prototypes for a large 6,000 kg human-class Lunar Pressurized Rover (LPR) and a smaller 500 kg Precursor to Human and Science Rover (PHASR) that could one day be used to support human exploration missions. The wheels needed to be lightweight and remain durable for 2,000 km (LPR) and 600 km (PHASR).

Canadensys came up with several wheel concept designs for the two rover configurations. Once this was accomplished, the next step was to build, test prototypes and develop technology road mapping and other program inputs that would support future CSA program planning.

"Reinventing the wheel"

The lunar environment can be incredibly hostile. Temperatures swing from about -200 °C (at which rubber would shatter like glass) to 130 °C (which would cause the rubber to degrade rapidly). Additionally, the lunar surface is covered in a layer of fine, highly abrasive grained dust which wreaks havoc with the moving parts of machinery. The SWARM wheel prototype addressed these challenges, borrowing design elements from multiple generations of CSA lunar rover wheel prototypes. The SWARM PHASR concept prototype consists of 20 ground-contacting traction plates, each of which is located by a pair of leaf springs and a pair of tension cables. The larger 90 cm diameter LPR wheel had the same general construction but consisted of 30–35 traction plates rather than 20.

Sequence of photos showing the large wheel undergoing high-speed impact testing. (Credit: Canadensys)

The SWARM testing experience

Extensive and rigorous durability testing was a critical component of the SWARM project. It was essential that wheels were efficient and dependable and would allow rovers to move around freely and easily. Canadensys assessed wheel traction and stiffness and conducted some initial thermal vacuum (TVAC) testing. The wheels were loaded to simulate capacity and tested at the Dust Utilizing Space Terrain Environment (DUST-E) lab, a special room that reproduces the dusty conditions of the lunar surface using a lunar regolith (soil) simulant. Soon, the wheel would need to be tested dynamically in a thermal vacuum chamber that can reproduce the vacuum conditions of space and bring the temperature down as low as -230 °C.

Photo caption: The dusty durability test bed. The wheels are attached to and driven by a rover power train while the circular testbed revolves. This picture was taken before the dust was added. It was never this clean again! (Credit: Canadensys)

A closer look at a pair of wheels on a rover drive system. Some lunar dust simulant has been added to the turntable, and the wheels have made their first tracks. (Credit: Canadensys)

Large SWARM wheel undergoing a 2,000 km durability test in dusty conditions. (Credit: Canadensys)

Once the design had been adjusted based on initial testing, the real work began, and Canadensys embarked on one of the longest testing experiences ever conducted on a wheel of this kind. The smaller PHASR wheel was tested for durability over 600 km and the larger LPR wheel for 2,000 km. Canadensys created a unique five-metre diameter turntable wheel test bed/apparatus to place the wheels on and drive them until they reached these distances. Canadensys also incorporated other elements to simulate the abrasive and sticky dust found on the Moon and added boulders and rocks similar to rough lunar terrain. The wheels were loaded and mounted on this device and driven continuously day after day for eight months! This was an extremely noisy test and when the wheels hit a rock/obstacle, the sound reverberated throughout the entire facility.

The smaller wheel made it to 600 km (the distance between Toronto and Montreal) and the larger wheel was still going strong after 1,917 km (the distance between Vancouver and Regina) when the testing bed broke down.

"Graceful degradation"

The lunar surface is dusty, rocky and covered with dead volcanoes, impact craters and solidified lava flows. Lunar rovers must be able to navigate very soft surfaces (similar to a beach) as well as very rough and rocky surfaces (like a dried-up riverbed). There are also unknown regions on the Moon that are permanently shadowed and may contain a higher water content that might affect soil properties. Given these known and unknown travel impediments, vehicle damage is inevitable. On Earth when we blow a tire, it's game over. We stop everything and fix it. That isn't possible on the Moon. Rover wheels need to be able to withstand some breakage and yet continue to function. In other words, they need to be able to "gracefully degrade."

"Even when things break down on the Moon, the wheels still need to function."

Thankfully, the metal SWARM wheel design is much more resilient and can withstand damage to its component parts without breaking down completely. Even if parts of the wheel fail, the entire wheel will not be debilitated.

SWARM contributions to Canada's role in space exploration

The SWARM wheel will play a significant role in preparing and positioning Canada as a leader in future space exploration. Much like the lunar landing gear developed by Héroux in the s, the SWARM wheel offers a specialized and unique on-the-ground technology that is in direct contact with the surface of the Moon and other planets.

Our experience developing the SWARM wheels has also provided a group of Canadian engineers with considerable experience in designing, fabricating, testing, and adapting innovative and crucial technology.

Looking forward: How can the SWARM wheel experience benefit us here on Earth?

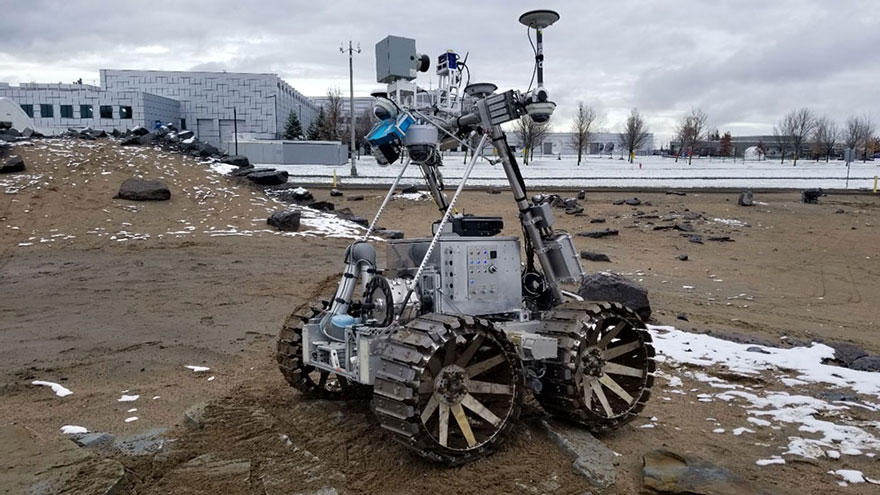

Although rubber will likely remain the favoured choice for wheels on Earth, the SWARM wheel offers unique advantages for transportation on rough and uneven terrain. Canadensys has leveraged its experience with the SWARM project in the design of other wheels that are used on high-traction terrestrial vehicles that operate in changing and dynamic conditions. They have also developed a large, extreme terrain vehicle called HAWC that can be operated both as a robotic vehicle and as a crewed vehicle.

The SWARM wheel experience is also helping us better understand how to develop vehicles that can adapt to shifting temperatures and natural disasters (flooding, hurricanes, wildfires, etc.). As we move into the future, it will be essential that we have the capacity to adjust existing technologies to meet these challenges.

"The engineering methods we've developed through our contract with the CSA have worked well for terrestrial markets. We are using the same team that developed the SWARM wheel to develop high-traction wheels for off-road use such as mining, logging, and defence applications."

According to Peter Visscher, "Our experience with the SWARM wheel taught us to think outside the box (or circle if you wish) and come up with innovative and unique solutions for extreme conditions in both space and terrestrial applications."