Maritime Monitoring and Messaging Microsatellite (M3MSat)

Launch:

Status: Active

Mission accomplished!

M3MSat has successfully demonstrated technologies and delivered high-quality data. As of , M3MSat embarked on a new commercial services mission under the ownership of a private Canadian company. M3MSat was previously owned by DRDC, and operated by the CSA.

The Canadian Maritime Monitoring and Messaging Microsatellite (M3MSat) is the latest of small-but-mighty spacecraft sent to test innovative technologies in space before they're deployed on full-scale missions. The mission aims to improve Canada's space-based capabilities to detect ships and manage marine traffic. It is also testing a device that could change the way we monitor the health and safety of satellites.

M3MSat demonstrates the kinds of unique solutions that space and new technologies can provide. It is a great example of collaboration between government, industry and academia to drive innovation in Canada's space sector.

2016-06-21 - Canada's Maritime Monitoring and Messaging Microsatellite (M3MSat) was launched successfully by the Indian Space Research Organisation, from Sriharikota, India. (Credit: Door Darshan (DD))

Enhancing Canada's capabilities for monitoring maritime traffic from space

Automatic Identification System (AIS) technology transmits important information on ships' identity, heading and speed. Ships use AIS signals to detect other ships and avoid collisions at sea, and coastal authorities use them to enhance marine safety and monitor maritime traffic.

The placement of AIS technology on satellites in recent years has revolutionized how we monitor and manage marine safety by providing a more complete view of maritime traffic. One of the main objectives of M3MSat is to build on and improve Canada's space-based AIS capabilities.

Part of M3MSat's mission is to test an AIS antenna with advanced capabilities that promises higher performance for identification and conflict resolution of the signals. The compact antenna was designed by the University of Waterloo and is the first and only one of its kind.

Another objective of the mission, is to test a device, the Low Data Rate Service (LDRS), to ensure surveillance and data continuity when AIS receivers cannot provide real-time coverage. The LDRS receives transmissions collected by stations in remote areas such as the Arctic. Then it passes the information on to Canadian marine traffic control centres.

Improving the way we monitor the health and safety of satellites

The accumulation of static energy in a satellite is detrimental to its electronics. While it is possible to reduce the charge by raising the temperature of the spacecraft temporarily, we currently have no way to determine when that needs to be done. M3MSat is testing the Dielectric Deep Charge Monitor (DDCM), a device designed to measure the static energy that has accumulated in the satellites' electronics. If successful, the DDCM could improve the way we build and monitor the health and safety of satellites, and help extend the life of satellites in orbit.

Did you know?

- In-orbit technology demonstration is the last step for space technology development.

-

It benefits industry and the government by providing essential experience and evidence of flight heritage for emerging technologies and can facilitate quicker access to the market.

- AIS signals travel in a straight line.

-

Until recently, Automatic Identification System (AIS) technology was not able to provide information on ships as far away as 100 km, even though AIS transponders can transmit hundreds of kilometres. However, the signal travels in a straight line and cannot follow the curvature of the Earth. In fact, this challenge is what led to the development of satellite-based AIS. M3MSat can collect the signals transmitted from every ship within its field of view—a radius of about 2500 km!

- Satellites: from big to small to smaller...

-

Technological advancement seems to be synonymous with miniaturization. Just think about the first computers and mobile telephones compared to what we have today. Space technology is no exception. In a field where smaller, lighter materials are more economical to make and launch, microsatellites are on the rise. The term microsatellite usually refers to satellites that are between 10 and 100 kilograms.

Mission overview: The satellite, testing, launch and operations

The satellite

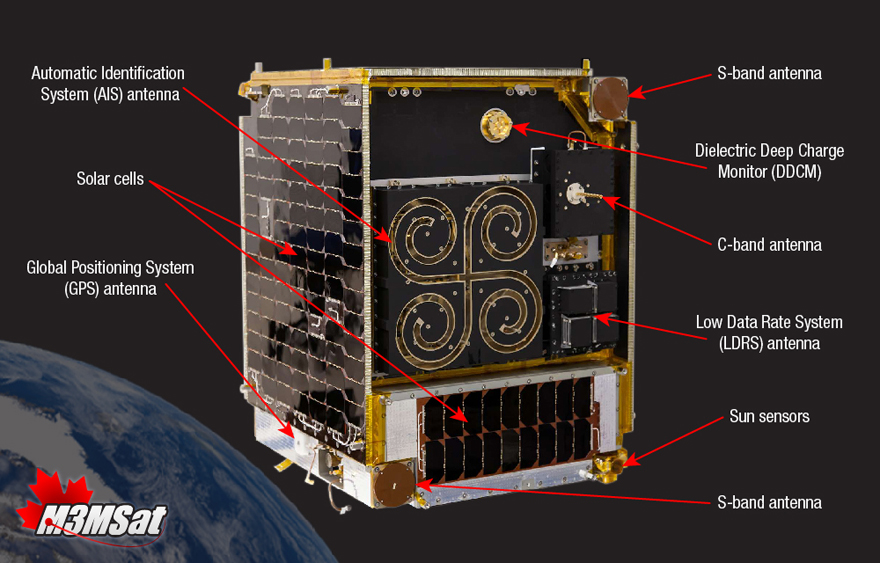

The microsatellite's box-shaped frame weighs about as much as the average Canadian male (85 kilograms) and is the size of most household dishwashers. It uses a new type of generic satellite platform design (developed by the University of Toronto Space Flight Lab) that could be used for future missions. The graphic below illustrates the main components of the spacecraft.

Text version

Components of M3MSat

The image identifies the main components of the M3MSat spacecraft. The satellite's box-shape frame uses a new type of generic satellite platform design and is about the same size as most household dishwashers. The following components are part of the satellite, listed clockwise from the top right: S-band antenna; C-band antenna; Low Data Rate System (LDRS) antenna; Sun sensors; S-band antenna; Global Positioning System (GPS) antenna; Solar cells; Automatic Identification System (AIS) antenna; Dielectric Deep Charge Monitor (DDCM).

Credit: Honeywell (Formerly COM DEV)

Space qualification testing

In preparation for the intense experience of a rocket launch and the extreme temperatures associated with space flight, M3MSat has undergone a series of critical tests. Many of these were completed at the Canadian Space Agency's (CSA's) David Florida Laboratory (DFL), Canada's world-class spacecraft assembly, integration and testing centre located in Ottawa.

Launch

M3MSat was launched by the Indian Space Research Organisation (ISRO) from Sriharikota, India. It lifted off aboard a Polar Satellite Launch Vehicle (PSLV) along with Canadian company GHGSat's first demonstration satellite. GHGSat is testing a new way to measure greenhouse gas emissions from industrial facilities. The company has benefitted from CSA funding, both through the Space Technology Development Program and the Earth Observation Applications Development Program.

Operations

Since its launch, M3MSat is circling the Earth from pole to pole at an altitude of 505 km. It travels over Canadian waters approximately ten times a day. The satellite is owned by the Defence Research and Development Canada (DRDC) and operated by the Satellite Operations Centre at the CSA. Operators can use AIS aboard M3MSat independently or in conjunction with RADARSAT-2 by comparing Synthetic Aperture Radar (SAR) images with information captured by M3MSat.

Partners

M3MSat is a joint mission of the CSA and DRDC. The CSA is responsible for the LDRS and DDCM instruments, and DRDC is responsible for the AIS. The satellite was built by Ontario-based company COM DEV International (now Honeywell Canada), with support from the University of Toronto Institute for Aerospace Studies and the University of Waterloo.